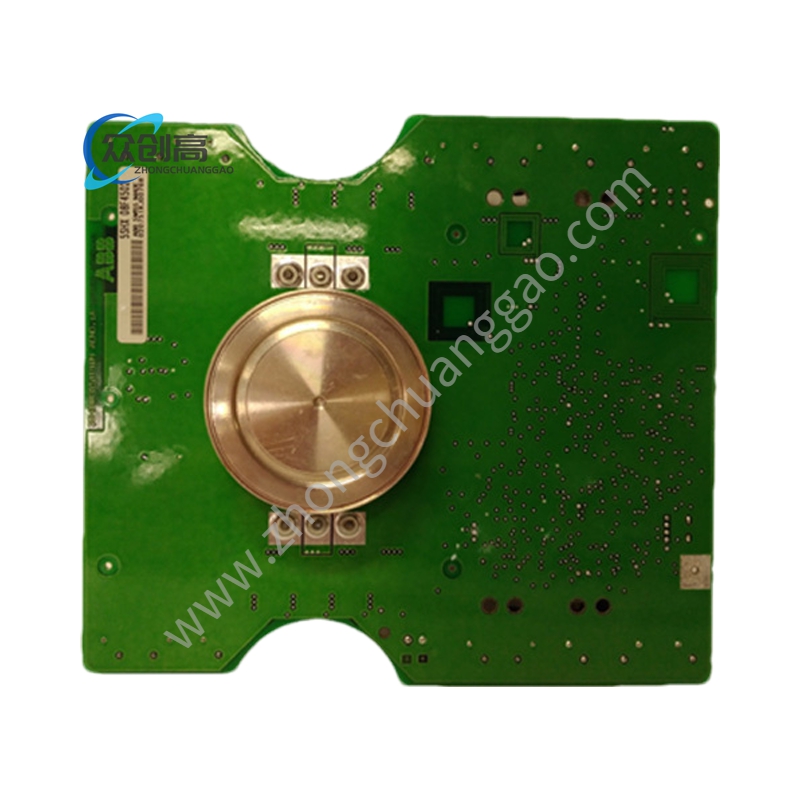

ABB PFCL201C-20.0KN不同负载和速度条件下稳定运行

是一种先进的电机控制技术,它可以根据电机的运行状态和负载情况自动调整控制参数,实现更高效、更精准的控制。

在自适应控制中,电机控制器会根据电机的电流、电压、转速等实时监测数据,以及电机的类型、额定参数等信息,动态调整控制算法中的参数,以适应不同的电机特性和运行状态。这使得电机能够更好地跟踪预设的运行轨迹,提高控制的精准度和响应速度。

电机自适应控制还可以实现以下功能:

1. 负载辨识:根据电机的运行数据,自适应控制器可以对电机的负载情况进行实时辨识,从而更好地掌握电机的运行状态。

2. 参数优化:根据电机的运行数据和负载情况,自适应控制器可以不断优化控制算法的参数,以提高电机的控制效果和运行效率。3. 故障诊断:自适应控制器可以实时监测电机的运行数据,一旦发现异常情况,立即进行故障诊断和报警提示,有效预防故障的发生。

4. 能效优化:通过精准的控制和优化算法,自适应控制器可以显著降低电机的能耗,提高能效比。

5. 远程监控:自适应控制器可以与上位机或云平台进行数据传输和远程监控,方便用户进行设备管理和试。

电机自适应控制技术可以提高电机的控制效果、运行效率和稳定性,降低能耗和故障率,是工业自动化生产中不可或缺的重要技术之一。

它可以根据电机的实时运行状态和负载情况自动调整控制参数,实现更精准、更高效的电机控制。

这种控制方法具有以下优点:

1. 更高的控制精度:自适应控制可以根据电机的实时运行状态和负载情况动态调整控制参数,从而更好地跟踪预设的运行轨迹,提高控制的精度和响应速度。

2. 更高的运行效率:通过自适应控制,电机可以在整个运行范围内实现更高的运行效率,从而降低能源消耗和运营成本。

3. 更好的稳定性:自适应控制可以实时监测电机的运行状态,一旦发现异常情况,立即进行故障诊断和报警提示,有效预防故障的发生,提高系统的稳定性和可靠性。

4. 更低的维护成本:由于自适应控制可以实时监测电机的运行状态,因此可以及时发现潜在的故障或问题,减少维修停机时间,降低维护成本。

5. 更强的可扩展性:自适应控制可以通过软件升级或硬件扩展来满足不同类型和规格的电机控制需求,具有更强的可扩展性和灵活性。

是一种非常先进的电机控制方法,可以提高电机的控制效果、运行效率和稳定性,降低能耗和故障率,是工业自动化生产中不可或缺的重要技术之一。

It is an advanced motor control technology that can automatically adjust control parameters based on the operating status and load situation of the motor, achieving more efficient and accurate control.

It is an advanced motor control technology that can automatically adjust control parameters based on the operating status and load situation of the motor, achieving more efficient and accurate control.

In adaptive control, the motor controller dynamically adjusts the parameters in the control algorithm based on real-time monitoring data such as motor current, voltage, and speed, as well as information such as motor type and rated parameters, to adapt to different motor characteristics and operating states. This enables the motor to better track the preset operating trajectory, improving control accuracy and response speed.

Motor adaptive control can also achieve the following functions:

1. Load identification: Based on the operating data of the motor, the adaptive controller can identify the load situation of the motor in real-time, thereby better grasping the operating status of the motor.

2. Parameter optimization: Based on the operating data and load situation of the motor, the adaptive controller can continuously optimize the parameters of the control algorithm to improve the control effect and operating efficiency of the motor. 3. Fault diagnosis: The adaptive controller can monitor the operating data of the motor in real time. Once any abnormal situation is found, it immediately conducts fault diagnosis and alarm prompts, effectively preventing the occurrence of faults.

4. Energy efficiency optimization: Through precise control and optimization algorithms, adaptive controllers can significantly reduce motor energy consumption and improve energy efficiency ratio.

5. Remote monitoring: The adaptive controller can communicate with the upper computer or cloud platform for data transmission and remote monitoring, making it convenient for users to manage and test devices.

Motor adaptive control technology can improve the control effect, operational efficiency, and stability of motors, reduce energy consumption and failure rate, and is one of the indispensable and important technologies in industrial automation production.

The ABB PFTL201C-50KN motor adaptive control you mentioned is a very advanced motor control method that can automatically adjust control parameters based on the real-time operating status and load situation of the motor, achieving more accurate and efficient motor control.

This control method has the following advantages:

1. Higher control accuracy: Adaptive control can dynamically adjust control parameters based on the real-time operating status and load situation of the motor, thereby better tracking the preset operating trajectory and improving control accuracy and response speed.

2. Higher operating efficiency: Through adaptive control, the motor can achieve higher operating efficiency throughout the entire operating range, thereby reducing energy consumption and operating costs.

3. Better stability: Adaptive control can monitor the running status of the motor in real time. Once abnormal situations are found, fault diagnosis and alarm prompts are immediately carried out, effectively preventing the occurrence of faults and improving the stability and reliability of the system.

4. Lower maintenance costs: Due to the real-time monitoring of the motor's operating status through adaptive control, potential faults or problems can be detected in a timely manner, reducing maintenance downtime and maintenance costs.

5. Stronger scalability: Adaptive control can meet the control needs of different types and specifications of motors through software upgrades or hardware extensions, with stronger scalability and flexibility.

It is a very advanced motor control method that can improve the control effect, operating efficiency and stability of the motor, reduce energy consumption and failure rate, and is one of the indispensable and important technologies in industrial automation production.

SE-SW5U-WT SESW5UWT Automation Direct Optimation Inc Stride Ethernet Switch

1966 Optimization of nonlinear systems w/ inequality constraints Space Research

Tecmate Optimate 1 Duo #TM409

B&R 7CP474.60 - 1

B&R 7CP474.60 - 1  B&R 7AI354.7

B&R 7AI354.7  B&R 5PC810.SX02 - 00

B&R 5PC810.SX02 - 00  B&R 5C5001.11

B&R 5C5001.11