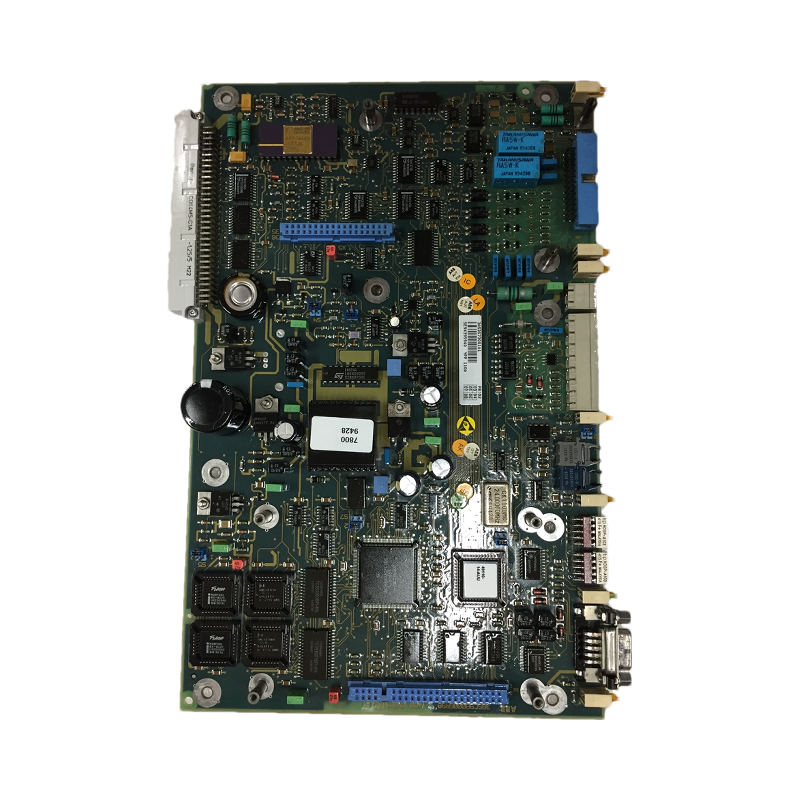

ABB XVC770BE101 3BHE021083R0101

控制类产品名目繁多,各家叫法不一。通常使用的控制类产品包括DCS、PLC两大类。

DCS经过多年的发展,积累了大量的算法模块。例如NETWORK6000+具有的设备级模块,在一个模块中集中完成了面向设备的基本控制和故障报警功能,在网络通讯中也已此模块为单位进行传递,大大提高了软件开发的效率。一个设备模块相当于0.5K的梯形图逻辑量,PLC要完成同样的功能,就要烦琐得多了。

PLC一般为大底版式机架,封闭式I/O模件,封闭式结构有利与提高I/O模件的可靠性,抗射频、抗静电、抗损伤。PLC模件的I/O点数有8点、16点、32点。

DCS集散控制系统(Distributed Control System)又称计算机分布式控制系统, 它是20世纪70年代中期迅速发展起来的,它是一个由过程控制级和过程级组成的以通信网络为纽带的多级计算机系统,它把控制技术、计算机技术、图像显示技术以及通信技术结合起来, 实现对生产过程的监视、控制和管理。它既打破了常规控制仪表功能的局限, 又较好的解决了早期计算机系统对于信息、管理和控制作用过于集中带来的危险性。它主要用于大规模的连续过程控制系统中, 如石化、电力等。其**是通信, 即数据公路。

它的基本要点是:

(1) 从上到下的树状系统, 其中通信是关键。

(2) PID在中断站中, 中断站联结计算机与现场仪器仪表与控制装。;

(3) 是树状拓扑和并行连续的链路结构, 有大量电缆从中继站并行到现场仪器仪表。

(4) 信号系统包括开关量信号和模拟信号。

(5) DCS是控制(站) 、操作(操作员站) 、现场仪表(现场测控站) 的3级结构。

PLC和DCS系统一般分别适用于离散和过程生产制造。使用PLC系统的离散生产制造设施,一般由单的生产装置组成,主要用于完成部件的组装,例如打标签、填充或研磨等。过程制造设施,通常使用自动化系统,以连续和批处理的方式按照配方而不是按件生产。大型连续加工设备,如炼油厂和化工厂,都使用DCS自动化系统。混合应用通常同时使用PLC系统和DCS系统。为某个应用选择控制器,需要考虑过程的规模、可扩展性和未来的较新计划、集成需求、功能、高可用性以及工厂设施整个生命周期的等等诸多因素。

There are a variety of control products with different names. The commonly used control products include DCS and PLC.

After years of development, DCS has accumulated a large number of algorithm modules. For example, the device level module of NETWORK 6000+integrates device oriented basic control and fault alarm functions in one module, and is also transmitted as a unit in network communication, greatly improving the efficiency of software development. A device module is equivalent to a ladder diagram logic quantity of 0.5K, and it is much more cumbersome for a PLC to complete the same function.

PLC generally adopts a large bottom layout rack with enclosed I/O modules. The enclosed structure is beneficial for improving the reliability of I/O modules, and is resistant to radio frequency, static electricity, and damage. There are 8, 16, and 32 I/O points for PLC modules.

DCS Distributed Control System, also known as Computer Distributed Control System, was rapidly developed in the mid-1970s. It is a multi-level computer system composed of process control level and process level, connected by a communication network. It combines control technology, computer technology, image display technology, and communication technology to achieve monitoring, control, and management of the production process. It not only breaks the limitations of conventional control instrument functions, but also effectively solves the danger caused by the excessive concentration of information, management, and control functions in early computer systems. It is mainly used in large-scale continuous process control systems, such as petrochemical, power, etc. Its * * is communication, which is the data highway.

Its basic points are:

(1) In a tree like system from top to bottom, communication is crucial.

(2) In the interrupt station, PID connects the computer with on-site instruments and control equipment.;

(3) It is a tree topology and parallel continuous link structure, with a large number of cables running parallel from relay stations to on-site instruments and meters.

(4) The signal system includes switching signals and analog signals.

(5) DCS is a three-level structure consisting of control (station), operation (operator station), and on-site instruments (on-site measurement and control station).

PLC and DCS systems are generally suitable for discrete and process production manufacturing, respectively. Discrete production manufacturing facilities using PLC systems typically consist of individual production units, mainly used to complete the assembly of components, such as labeling, filling, or grinding. Process manufacturing facilities typically use automated systems to produce according to formulas rather than parts in a continuous and batch manner. Large continuous processing equipment, such as refineries and chemical plants, all use DCS automation systems. Hybrid applications typically use both PLC and DCS systems simultaneously. Choosing a controller for a certain application requires considering factors such as the scale of the process, scalability, and future newer plans, integration requirements, functionality, high availability, and the entire lifecycle of the factory facility.

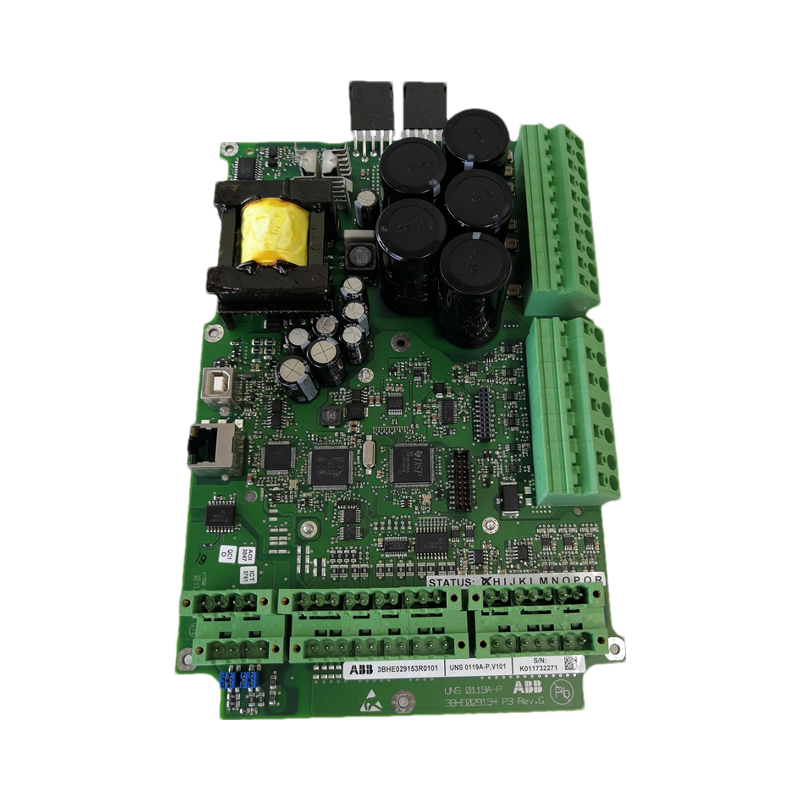

B&R 7CP474.60 - 1

B&R 7CP474.60 - 1  B&R 7AI354.7

B&R 7AI354.7  B&R 5PC810.SX02 - 00

B&R 5PC810.SX02 - 00  B&R 5C5001.11

B&R 5C5001.11