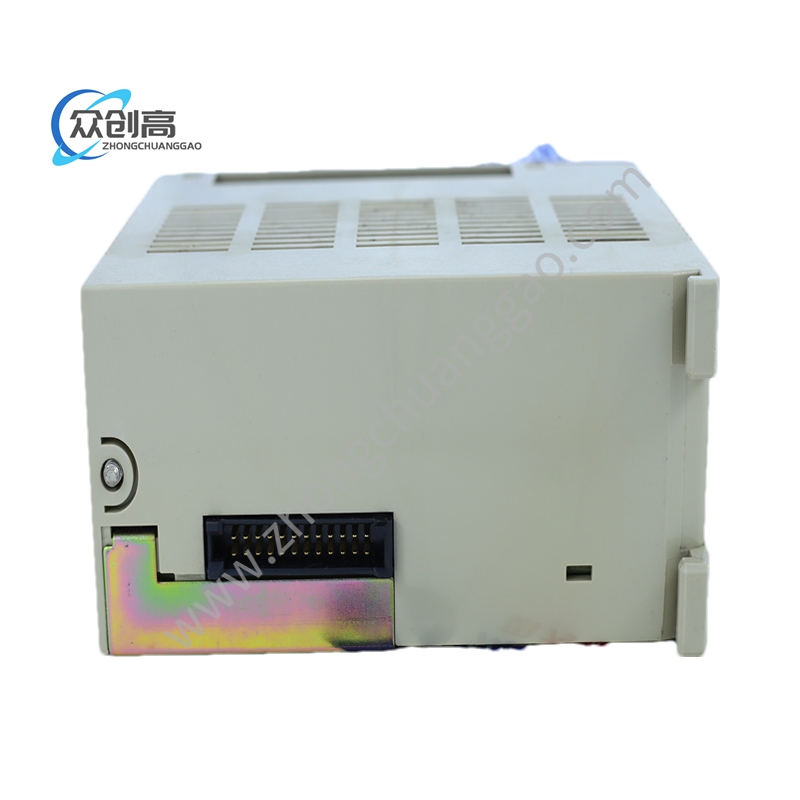

OMRON MY-4J

此外,数据可视化带来的另一个变化就是现场操作人员意识的提高。员工只需看一眼报表就能发现错误,对于整条生产线的全体员工来说,也更容易把握全局、扩大视野,而不再把目光只集中在自身所负责的环节当中。通过激发员工的生产积极性,最终使得整个生产制造进入良性循环,让人与机器默契协作的生产成为现实。

当下,中国制造2025战略正在稳步推进,其中,智能制造作为重点项目工程一直倍受关注。对于制造业企业来说,何谓“智能制造”?我们又将如何利用自身的优势助力智能制造。现在,欧姆龙控制技术与大数据的完美结合交出了一份答案。

In addition, another change brought about by data visualization is the improvement of awareness among on-site operators. Employees only need to glance at the report to detect errors, which makes it easier for all employees on the entire production line to grasp the overall situation and expand their horizons, instead of focusing solely on the aspects they are responsible for. By stimulating employees' enthusiasm for production, the entire production and manufacturing process can ultimately enter a virtuous cycle, making the production of people and machines working together in harmony a reality.

At present, the Made in China 2025 strategy is steadily advancing, and intelligent manufacturing, as a key project engineering, has always been highly concerned. What is "intelligent manufacturing" for manufacturing enterprises? How will we utilize our own advantages to assist intelligent manufacturing. Now, the perfect combination of Omron control technology and big data has delivered an answer.

OMRON S82K-05024快速响应

OMRON S82K-05024快速响应  OMRON R88M-K2K030C-BS2广泛的适用性

OMRON R88M-K2K030C-BS2广泛的适用性  OMRON R88A-MCW151-E易于编程和调试

OMRON R88A-MCW151-E易于编程和调试